Control Loop Performance Monitoring

Get insights into the effectiveness of your process control strategies.

Overview

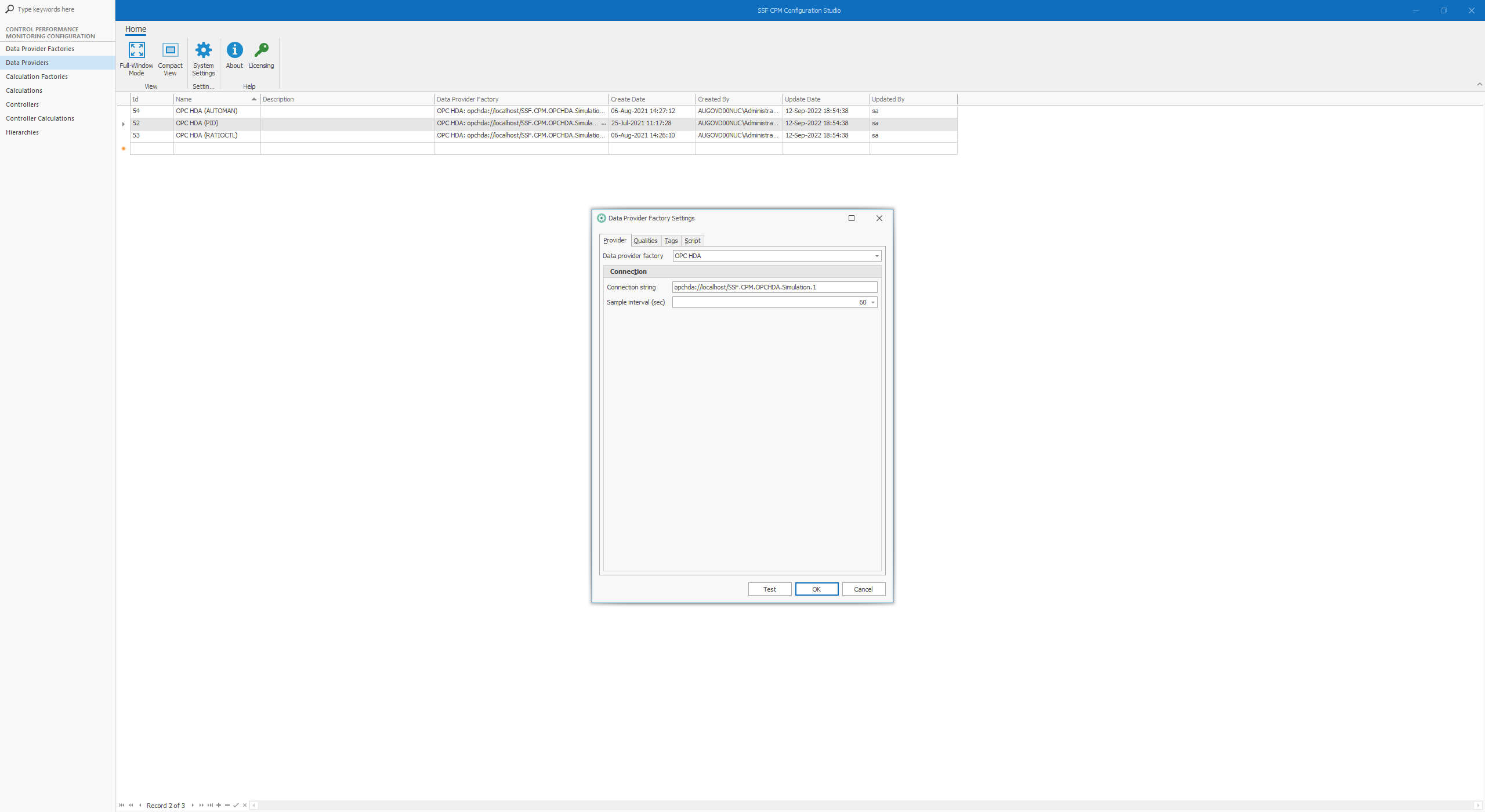

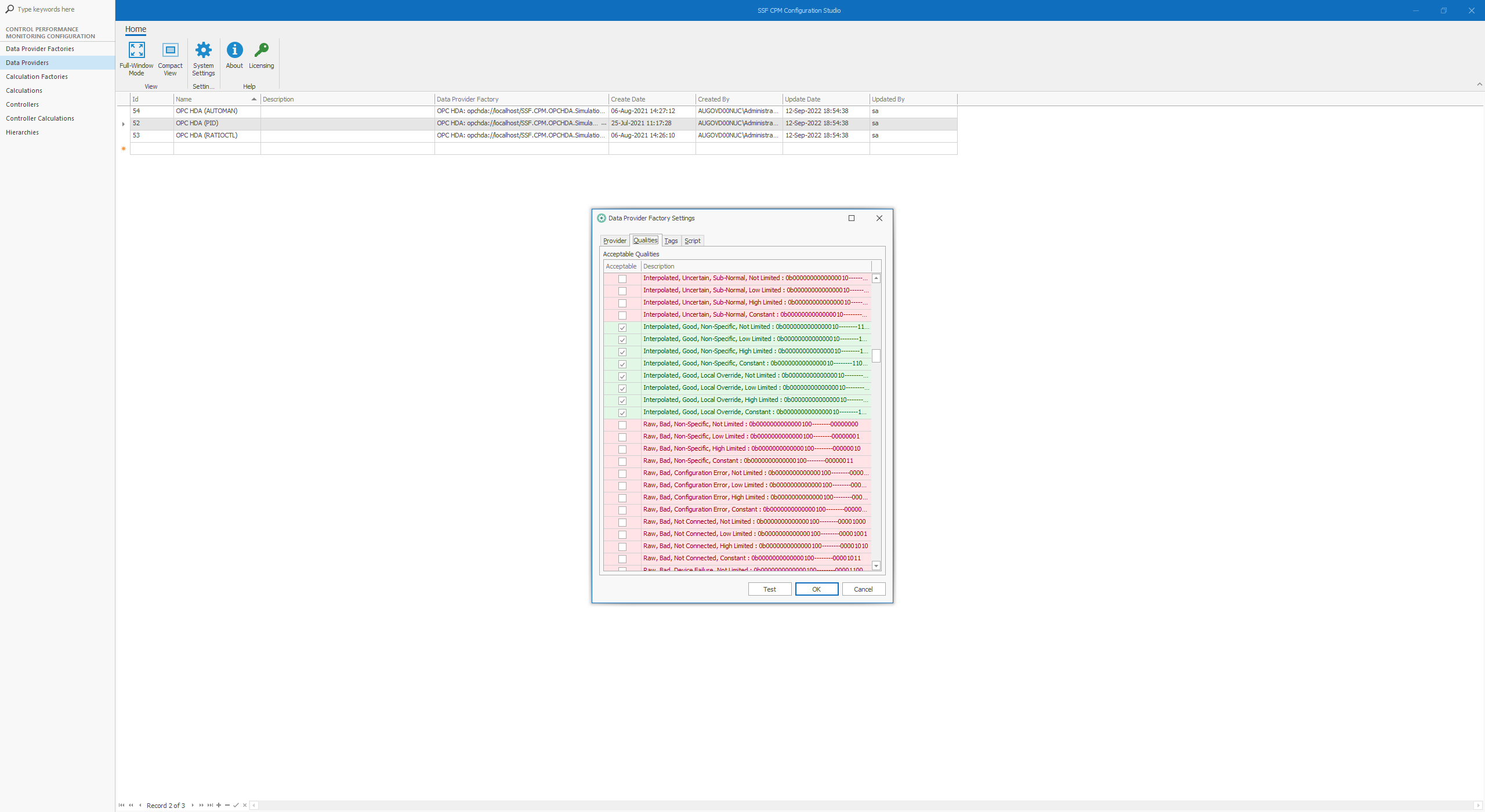

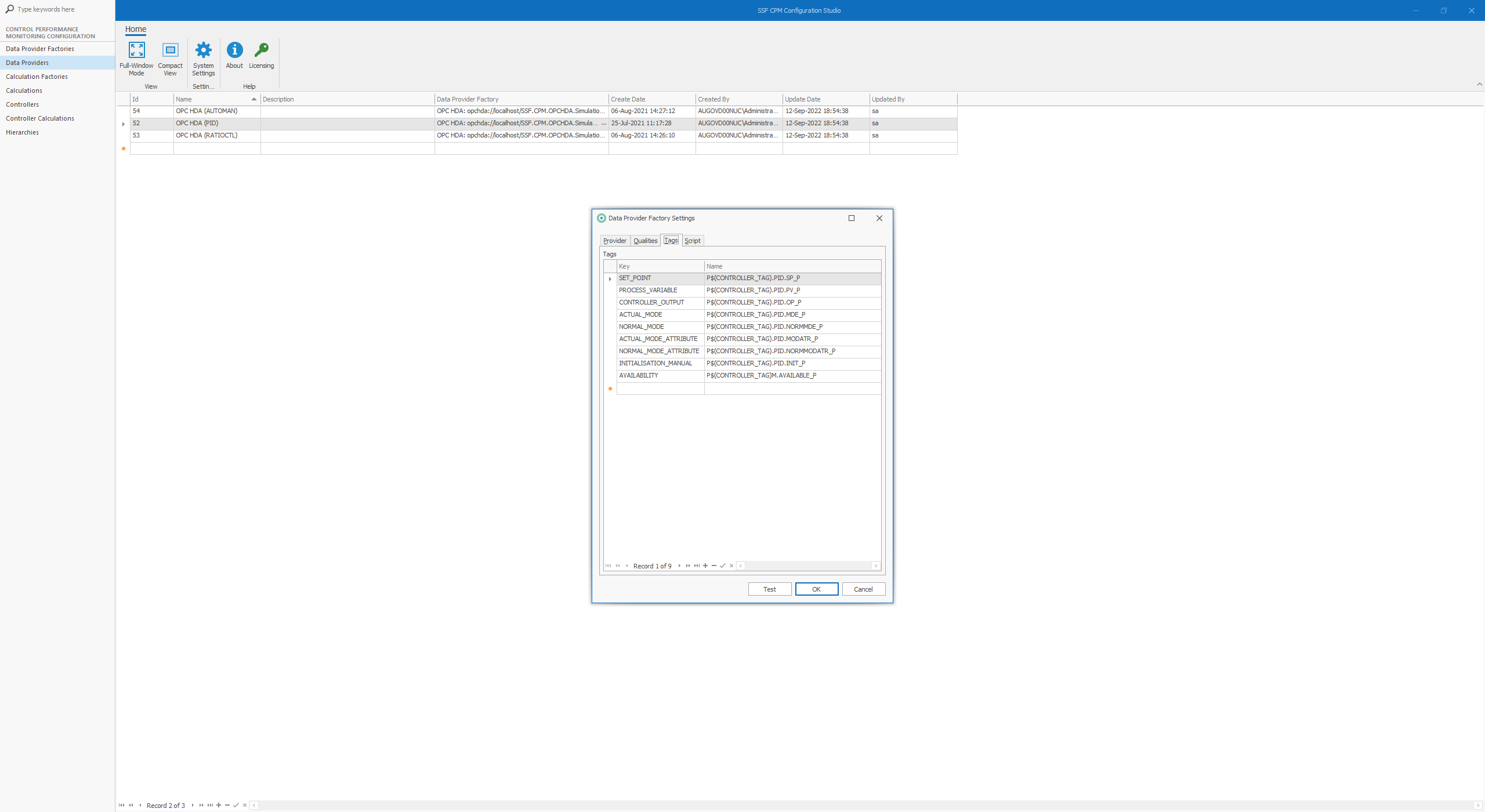

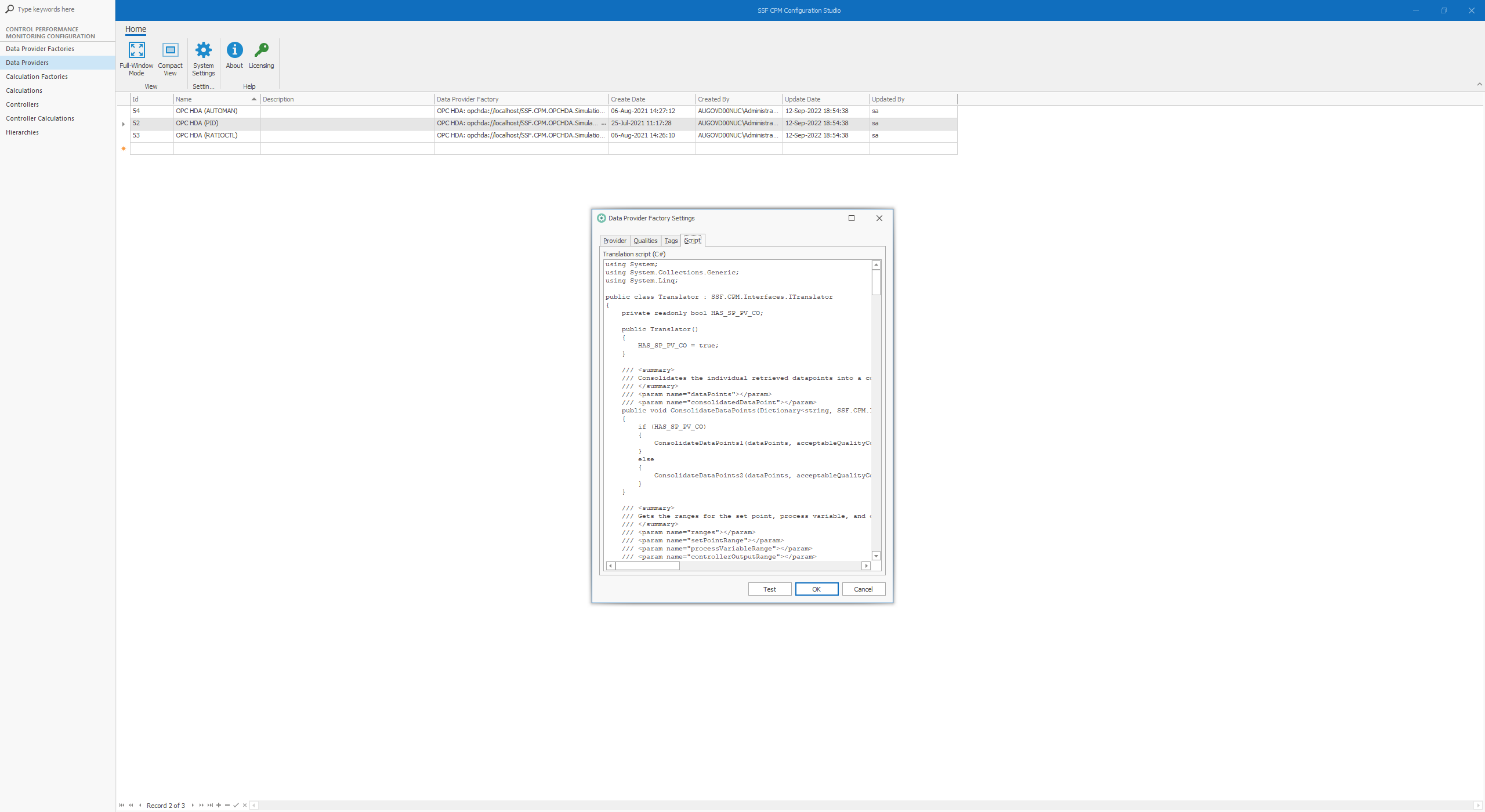

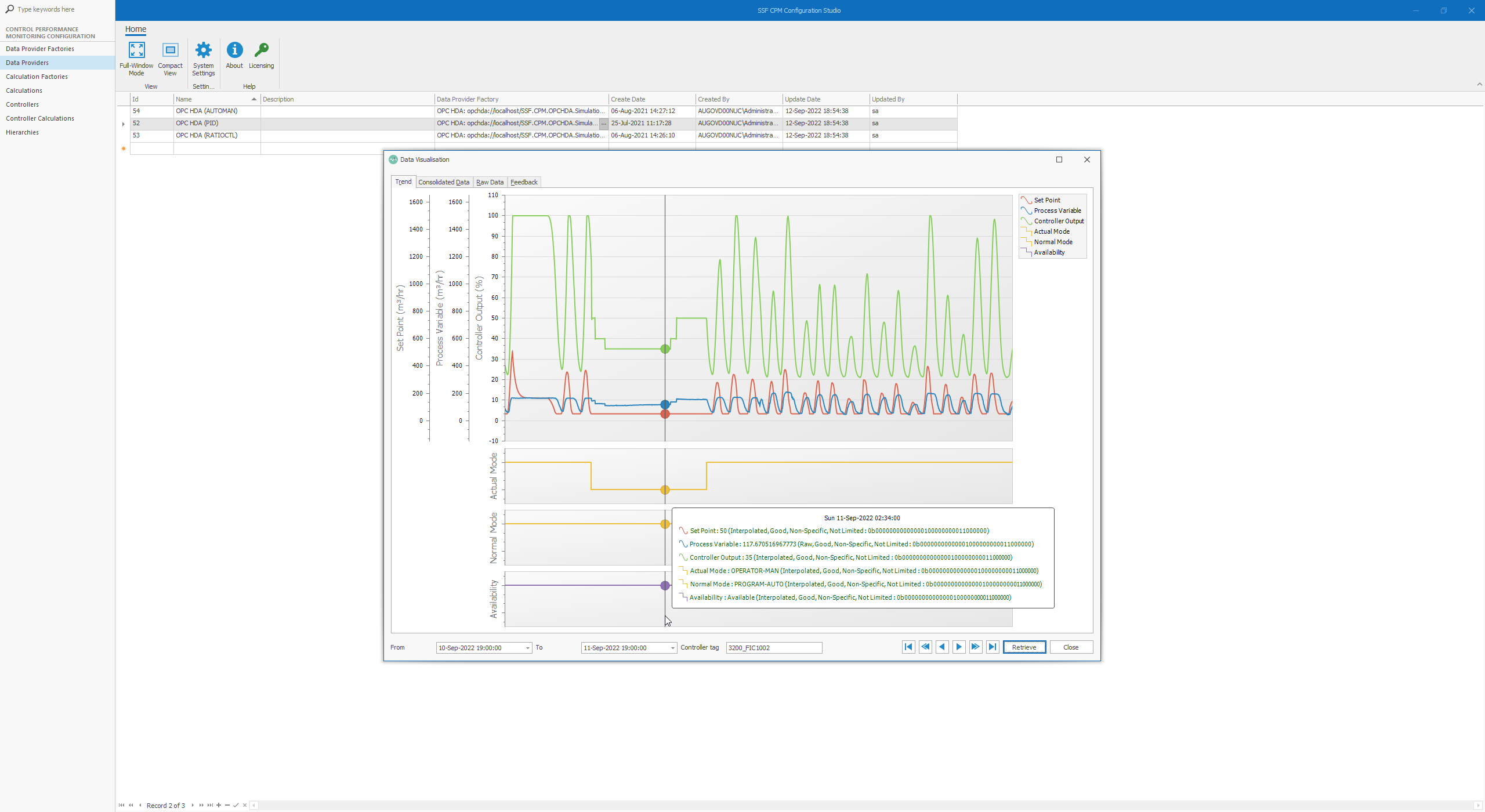

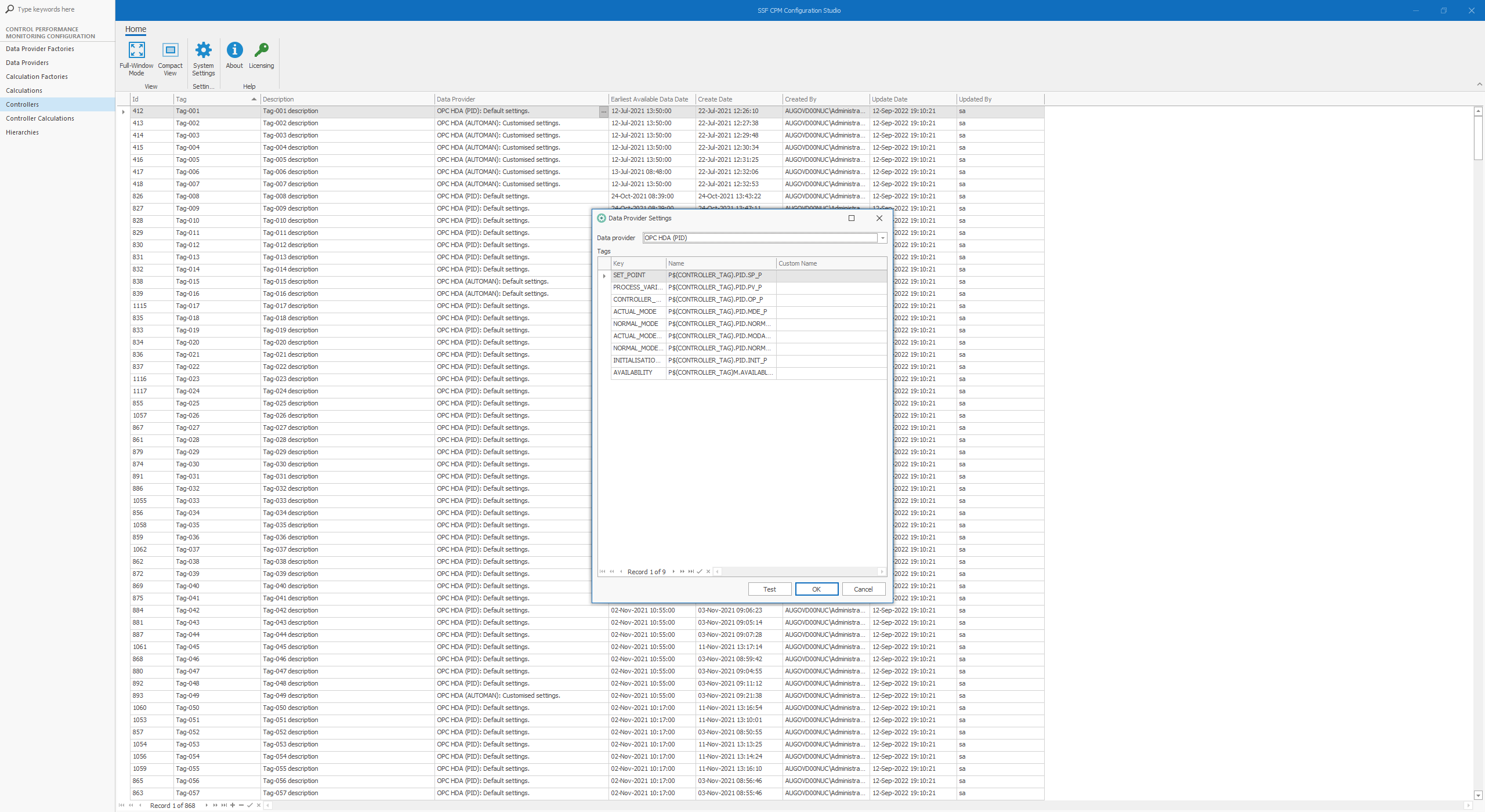

The control loop performance monitoring system actively monitors control loop performance using plant data from any time series data source, including any OPC HDA compliant historian & AVEVA PI historian via the PI-SDK. It is likely you already have the required tags configured in your historian. The control performance monitoring system has been developed & refined in an operational environment and is proven to ‘just work’ 24/7/365. The control performance monitoring system requires minimal configuration and can be configured to start collecting data and generating reports in a matter of hours by anybody with a basic level of computer system & control system literacy.

How It Works

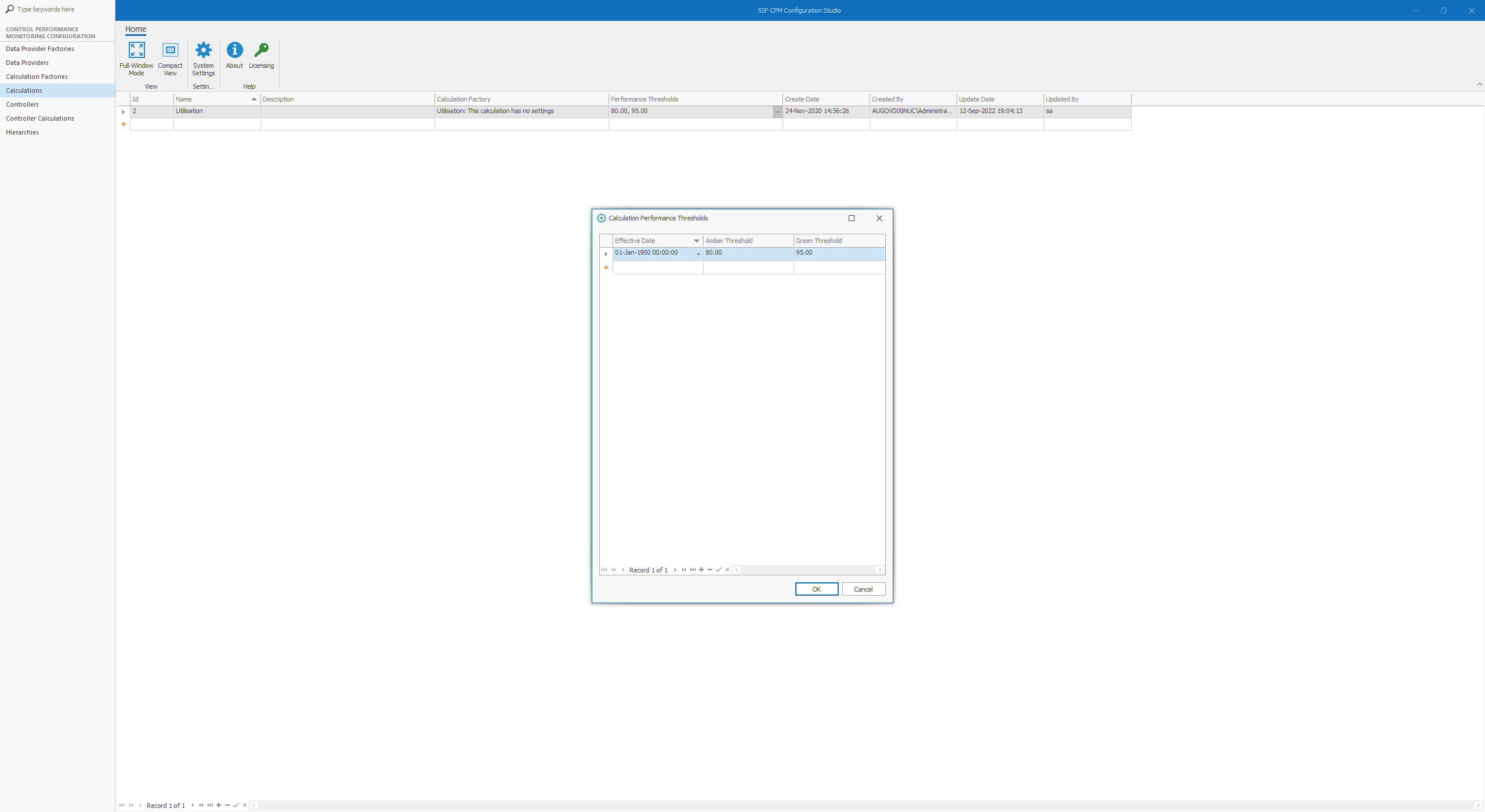

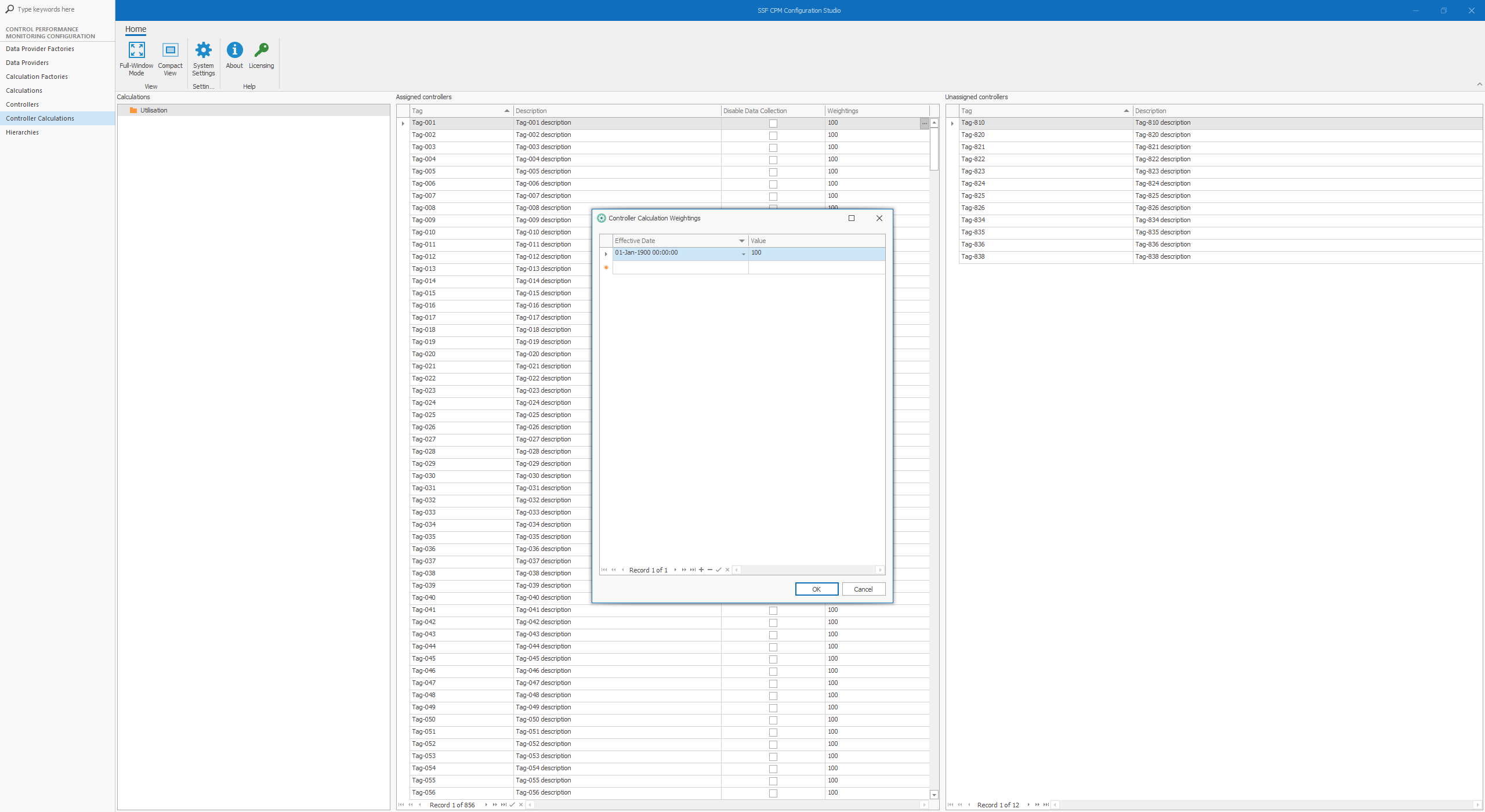

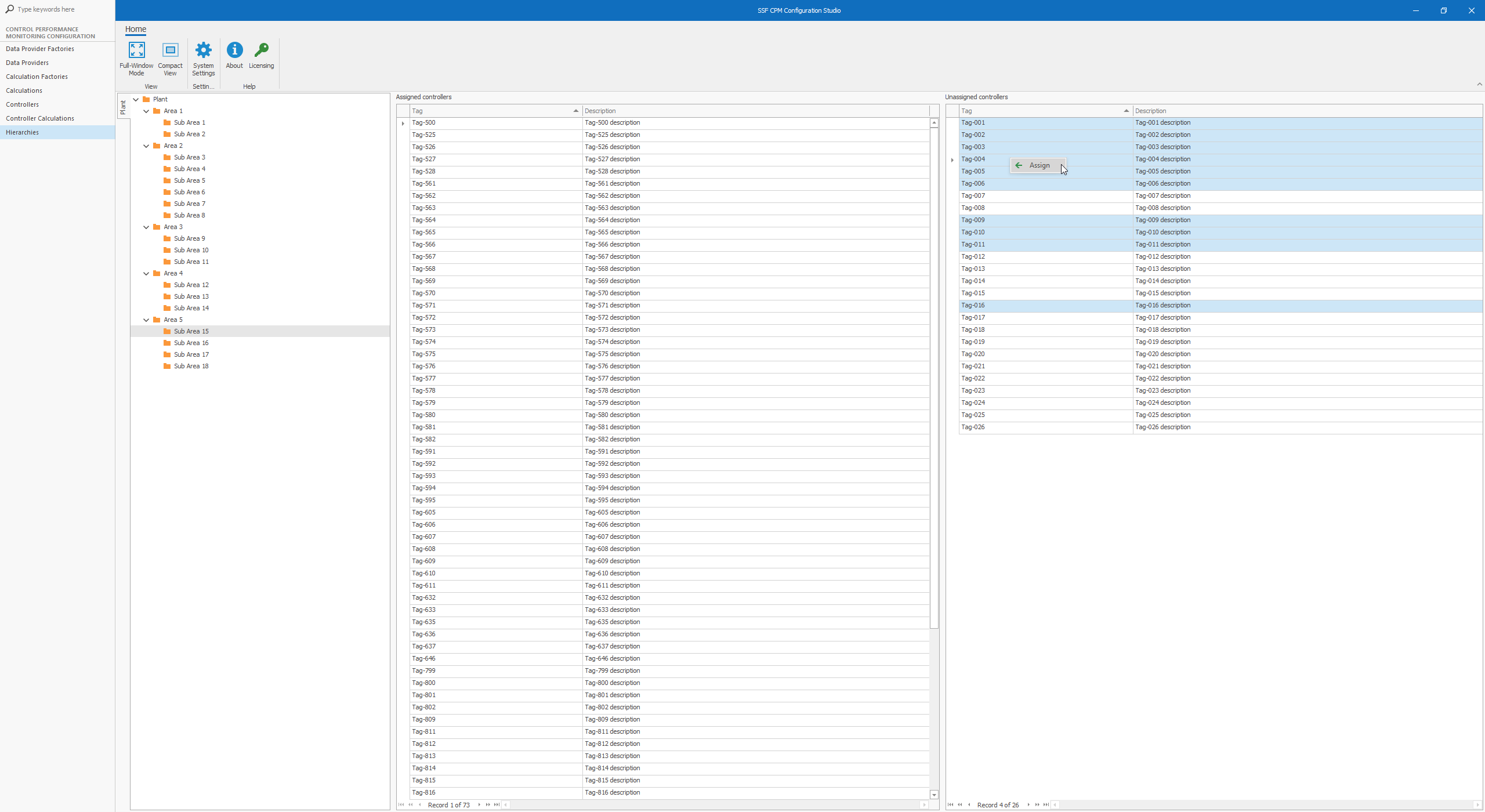

1. Via the CPM configuration application, loops are configured, calculations are configured, loop weightings are assigned, plant hierarchies are configured, and loops are assigned to an item in the plant hierarchy. This configuration is stored in the CPM database.

2. The CPM calculation engine reads the above configuration from the CPM database, retrieves loop data from the historian, calculates metrics, and writes the metrics back to the CPM database.

3. The CPM scheduled reporting engine reads scheduled report configuration and metrics from the CPM database and sends scheduled reports to end-users via an SMTP server.

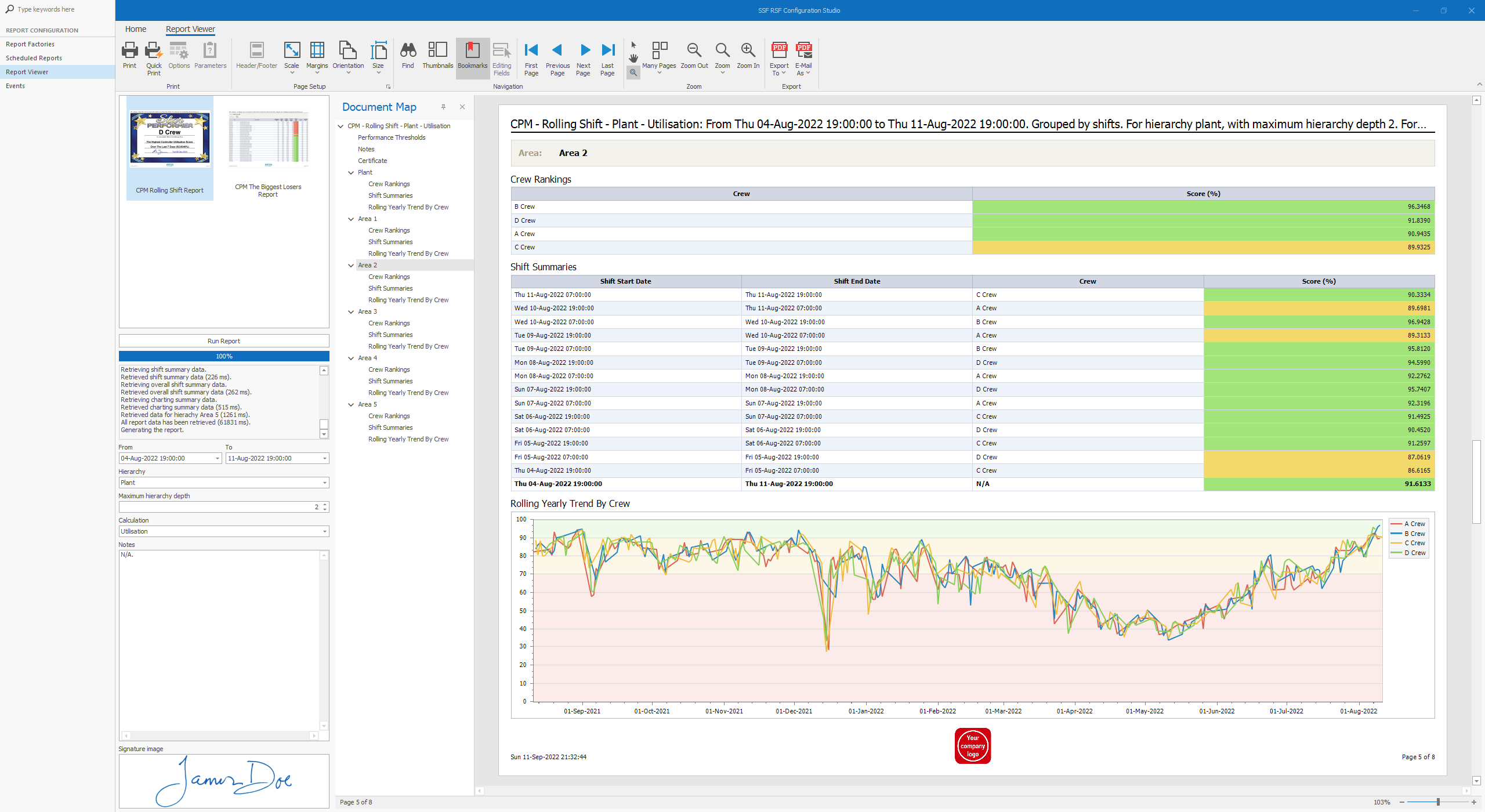

4. The CPM reporting application allows end-users to also run on-demand reports.

Features

Metrics are stored at 1-hour intervals so metrics can accurately be summarised in reports by hour, shift, day, week, month, quarter, or year.

Multiple plant hierarchies can be created to report on metrics by different groupings.

An optional availability tag can be used to exclude metric calculations when a control loop is unavailable (not in service).

Data can be read from any OPC HDA compliant historian.

Fault tolerant, and proven to 'just work'; 24/7/365.

Reports can be sent on a scheduled basis, or viewed on demand.

The ability to create an unlimited number of custom reports that are integrated into the system seamlessly (requires some basic .NET development skills).

Out-of-the-box reports that are appropriate for a number of audiences including, but not limited to, management, operations, process engineers, and control system engineers.

System Configuration

Pricing

Using the system with 50, or less, loops is free. A perpetual 50 loop licence is included in the download below.

For additional loops, blocks of annual user licences can be purchased as required.

Licence packs are cumulative. For example, if exactly 1650 loops are required, then buy 1 licence pack of 1000, 1 licence pack of 500, 1 licence pack of 100, and 1 licence pack of 50. You can do the math to work out if this is cost effective compared to just buying 2 licence packs of 1000, as larger licence packs are cheaper per loop.

- - Purchase a 50 loop licence pack : $600 AUD per year*.

- - Purchase a 100 loop licence pack : $1,100 AUD per year*.

- - Purchase a 250 loop licence pack. : $2,500 AUD per year*

- - Purchase a 500 loop licence pack : $4,500 AUD per year*.

- - Purchase a 1000 loop licence pack : $8,000 AUD per year*.

- - Purchase a 2500 loop licence pack : $17,500 AUD per year*.

- * Prices are exclusive of any applicable GST/VAT/GCT, which will be calculated after selecting your region/country on the purchasing page.

We use an e-commerce provider, FastSpring, to process payments. This allows us to sell around the world while focusing our efforts on the thing we do best; improving & supporting the software. If you require support during the licence purchasing process, first contact FastSpring consumer support. If they are unable to resolve the issue then contact us.

If you need to generate an invoice for your procurement department, then refer to the guide to generating an invoice.

If you need to register FastSpring as a supplier with your procurement department, then refer to the guide to setting up FastSpring as a supplier.

Download

SSF-CPM-2.0.0.1.7z 68 MB (Requires .NET Framework 4.7.2)

SSF-CPM-2.0.0.1.zip 279 MB (Requires .NET Framework 4.7.2)